Preamble

It is imperative to be able to test the quality of 3D printers, and to have a standard test procedure, in order to be able to test like for like, and accurately compare printers.

Featured image shows a 3D print exhibiting Y-slippage, source What could be causing my y axis to slip.

.

Test Protocol

See How to Evaluate the 2015 Make: 3DP Test Probes

The tests (source):

- Dimensional Accuracy

Dimensional Accuracy - Bridging Performance

Bridging Performance - Overhang performance

Overhang performance – 1

Overhang performance – 2 - Negative Space Tolerances

Negative Space Tolerances - Fine Positive Space Features Performance

Fine Positive Space Features Performance - Mechanical Resonance Test

- Mechanical Resonance in XY

Mechanical Resonance in XY - Mechanical Resonance in Z

Mechanical Resonance in Z

- Mechanical Resonance in XY

- Articulated Makey Robot

Articulated Makey Robot

Calibration

Whilst not entirely to do with testing, calibration is, nevertheless, an important part of making sure that the 3D printer is going to do what you want it to do.

Printing lots of simple 20 mm cubes can be a simple way of ensuring the printer is behaving.

Some very useful tips can be found on this page, 11 Experts Share Their Top 3D Printing Beginner Tips. The most salient points raised are:

- First, make sure that you understand that 3D printing at home is still not yet “ready for the average Joe”, despite the hype that many brands brag about

- Do not print with a badly calibrated printer!

- Never focus too much on one single issue

- My first general tip would be that when you first get a 3D printer up and running, print out lots of 20 mm cubes.

- My next tip, which really follows on from the above, would be to get comfortable with nozzle to print bed adjustment

- Then the same thing goes for print size calibration. When you print a 20mm cube, is it 20mm when measured? – if not check if it’s a calibration issue with the machine.

- Win if you can, lose if you must, but always cheat.

- Eat the elephant one bite at a time.

- In theory, theory and practice are the same but in practice, they’re different

- Get to know your printer.

- Take it apart when needed, that’s the only way to learn how to fix it. Stay calm and Fix.

- Use the force – forums, For an overall forum about 3D printing I recommend 3D Hubs Talk.

- The nr.1 mission is for the filament to stick to the build plate – tape, raft, glue are the best options for this.

- Make sure to always have your build plate calibrated (even the slightest difference can have a big impact).

- Changing filament can sometimes a little tricky- a little “human push” can help you a lot.

- 3D printing isn’t quite like magic yet.

- Get a little digital caliper.

- Learn how to design your own models right away. – Blender, Autodesk 123D Design (free)

- Choose a 3D printer that has good support available

- Find a good forum to engage in

- Learn to start designing using CAD

- 3D Printing Philosophy for Beginners:

- Inspect the printer to make sure it wasn’t damaged in shipping

- Setup the printer according to the manufacturer’s instructions

- Level and Calibrate the printer

- Slice your model using the manufacturer’s recommended slicer and settings.

- Don’t use transparent filament for your first print

- When photographing your models, use lots of light while avoiding glare

- Buy a roll of the manufacturer’s recommended filament when you purchase your printer

- Purchase two contrasting filament colours

- Take lots of photographs to document your prints

- Printing with PLA on blue painters tape is a great starting point.

- Getting the perfect extruder height is critical to great prints

- Invest time into your 3D modelling skills!

- Fix the weakest links until everything is perfect!

- Print responsibly! – Ventilate well and have a smoke detector. Lots of toxins are produced

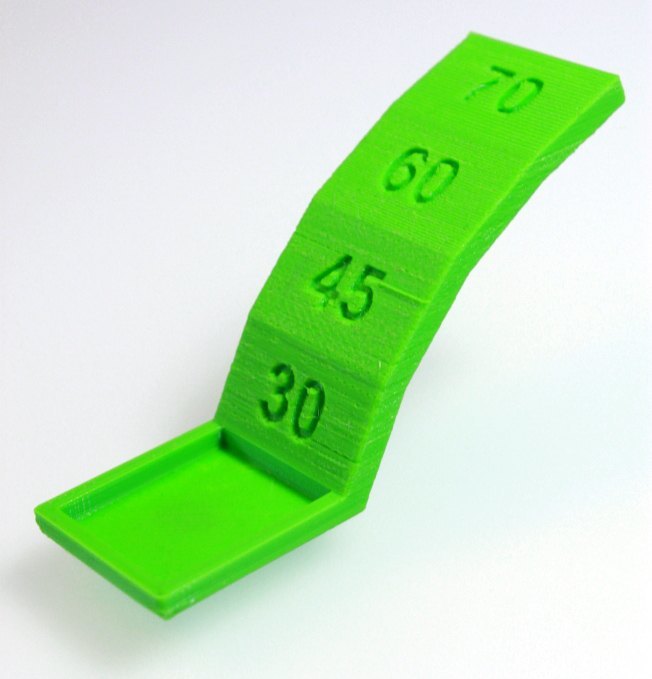

- The 45° Rule,

- Tolerance (0.25 mm), so there is a 0.5 mm gap between adjacent parts

- Persistence – producing many failed prints is normal

- Start slow and look up the basic knowledge

- Begin with easy to use, standard materials (PLA/ABS)

- The 3D printing learning curve is steep

- Focus on user experience instead of metrics when buying a 3D Printer

- Explore the world of exotic filament.

- Explore design tools and start creating yourself!

The main things to take away, from the above, are:

- Design yourself on 3D software

- Know your printer

- Calibrate

- Safety

- Document your progress

- Start simple and be patient